Overview

UK

Fashion

Product Lifecycle Management

for the fashion industry

Manufacturers, designers,

suppliers, and retailers

Project Snapshot

Our client is a UK-based garment technologist with years of experience working with global fashion brands. Having traveled extensively and worked hands-on with designers, factories, and suppliers, the client saw the industry’s challenges up close: fast-changing trends, scattered data, and endless Excel sheets trying to hold everything together..

Right from designs to store shelves, they witnessed how critical product details often got lost across files, emails, and manual processes. It slowed teams down, created miscommunication, and left no single source of truth for managing different products at scale. That’s when the client realized the gap and what the industry really needed: a dedicated Product Lifecycle Management (PLM) solution designed for the fashion industry.

The client relentlessly researched gaps that could be filled via automation. An initial solution was rolled out and tested by peers in the fashion industry. With the necessary feedback for improvement, they considered building a full-fledged PLM solution purpose-built for fashion products..

TOPS strategies in action

For building an end-to-end solution, the client had two clear expectations:.

- A team that understood the fashion industry’s niche and could identify the exact modules needed in a PLM solution.

- A team skilled with the latest technologies to build an advanced, future-ready platform.

After interacting with a few service providers, the client believed that TOPS aligned on both fronts. Our approach started with a deep dive into the industry’s pain points and workflows, ensuring that every feature we built served a real business need.

Building the tech stack– We selected a robust, modern tech stack that included Node.js, React.js, AWS, CKEditor, and React Grid Layout to guarantee scalability, performance, and long-term growth.

Defining the Must-Have Features– Through close collaboration and iteration, we identified the core areas that would make the most impact:

- Data consolidation: Eliminating silos by gathering data from spreadsheets, emails, and files into a single source of truth.

- Digitizing product lifecycle phases: Replacing manual, error-prone workflows with a digital-first PLM system tailored for fashion, covering everything from designs to purchase orders.

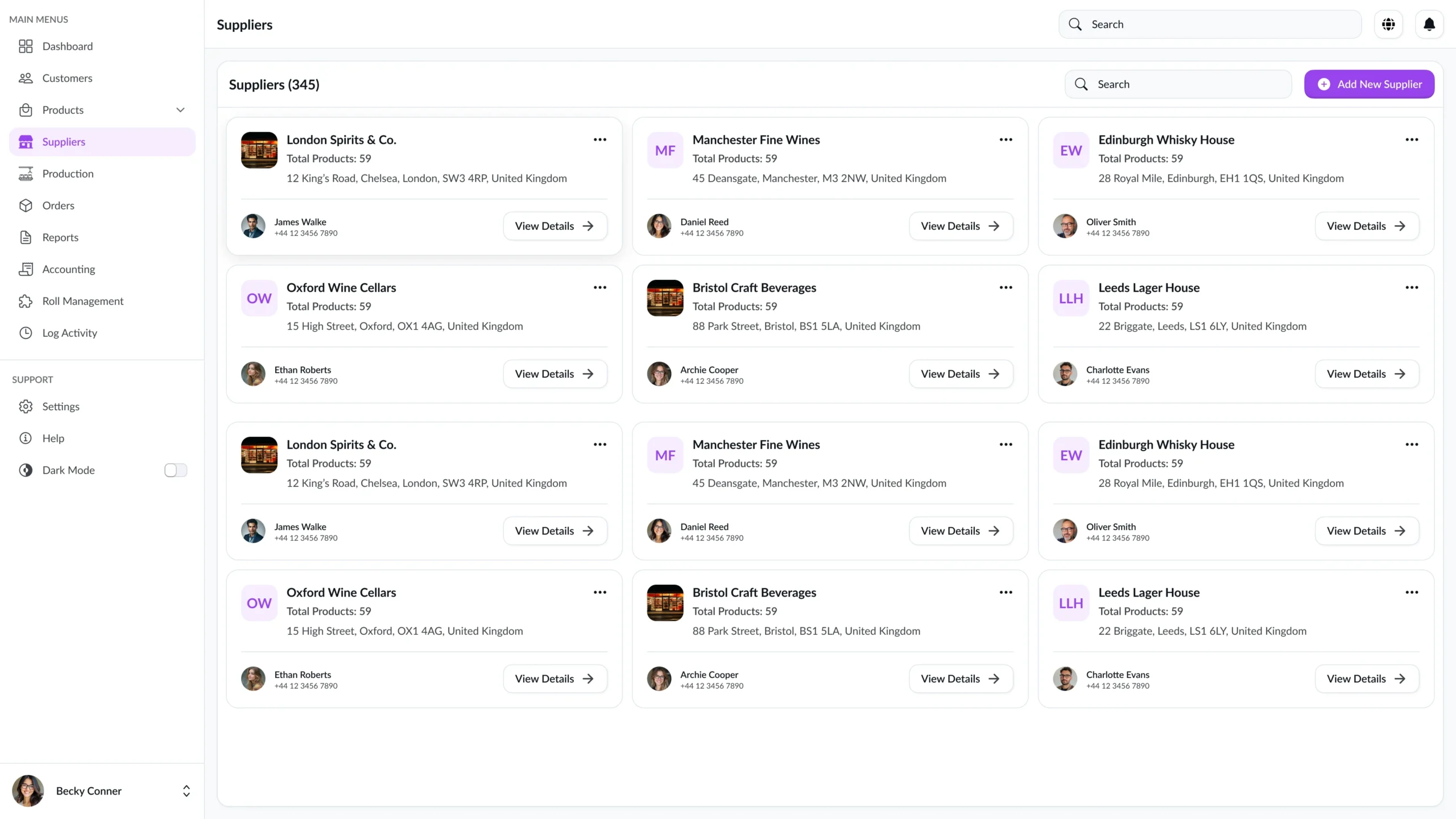

- Communication: Breaking down barriers between teams by enabling brands and suppliers to collaborate directly within the platform.

Challenges: What wasn’t working?

According to the client, major challenges for fashion brands stemmed from manual follow-ups and a lack of transparency that resulted in delays to market.

- Scattered data & siloed teams- Data existed on different platforms. Designs, BOMs, and specifications were stored across spreadsheets, emails, and folders. This made it difficult to maintain a single source of truth, making workflows prone to errors. It also led to miscommunication and longer product cycles.

- Manual workflows- Critical processes like sample tracking, approvals, and supplier coordination were all handled manually. This slowed down decision-making and increased the risk of mistakes, along with duplicated effort.

- Lack of visibility- There was no real-time visibility into product status or upcoming deadlines since not every stakeholder had access to data. Delays often went unnoticed until it was too late. This impacted speed-to-market and customer satisfaction.

- Compliance pressures- Managing certifications and environmental impact data across multiple systems was time-consuming and complex.

Solution: Product Lifecycle Management tool for the Fashion industry

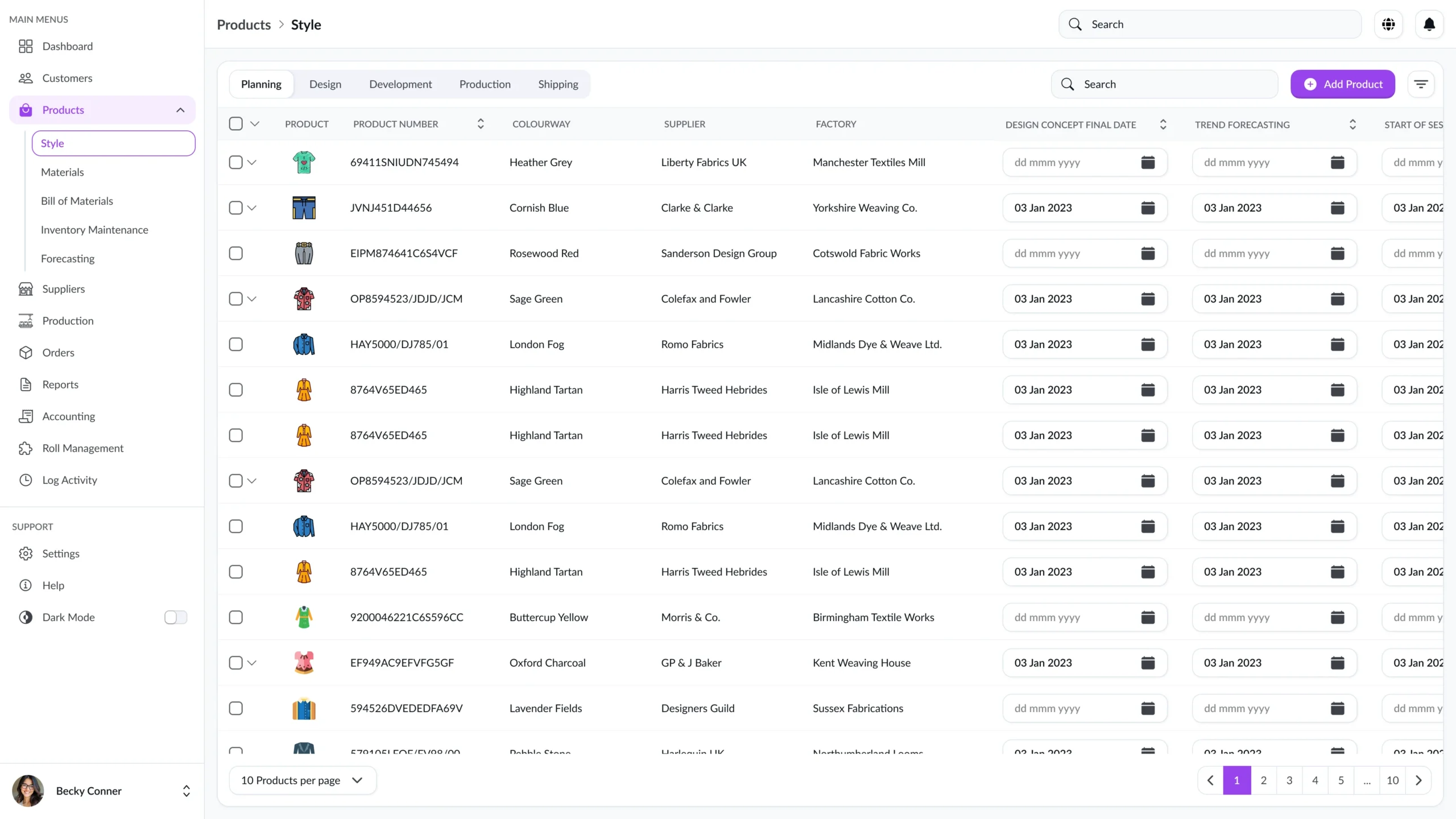

Considering the challenges, we first developed the features for every phase of the product life cycle on a user-friendly interface. This included:

Design inputs

Traditionally, designers would export files after creating designs via email or shared folders. We provided an Adobe Illustrator plugin that allows designs to flow directly into PLM.

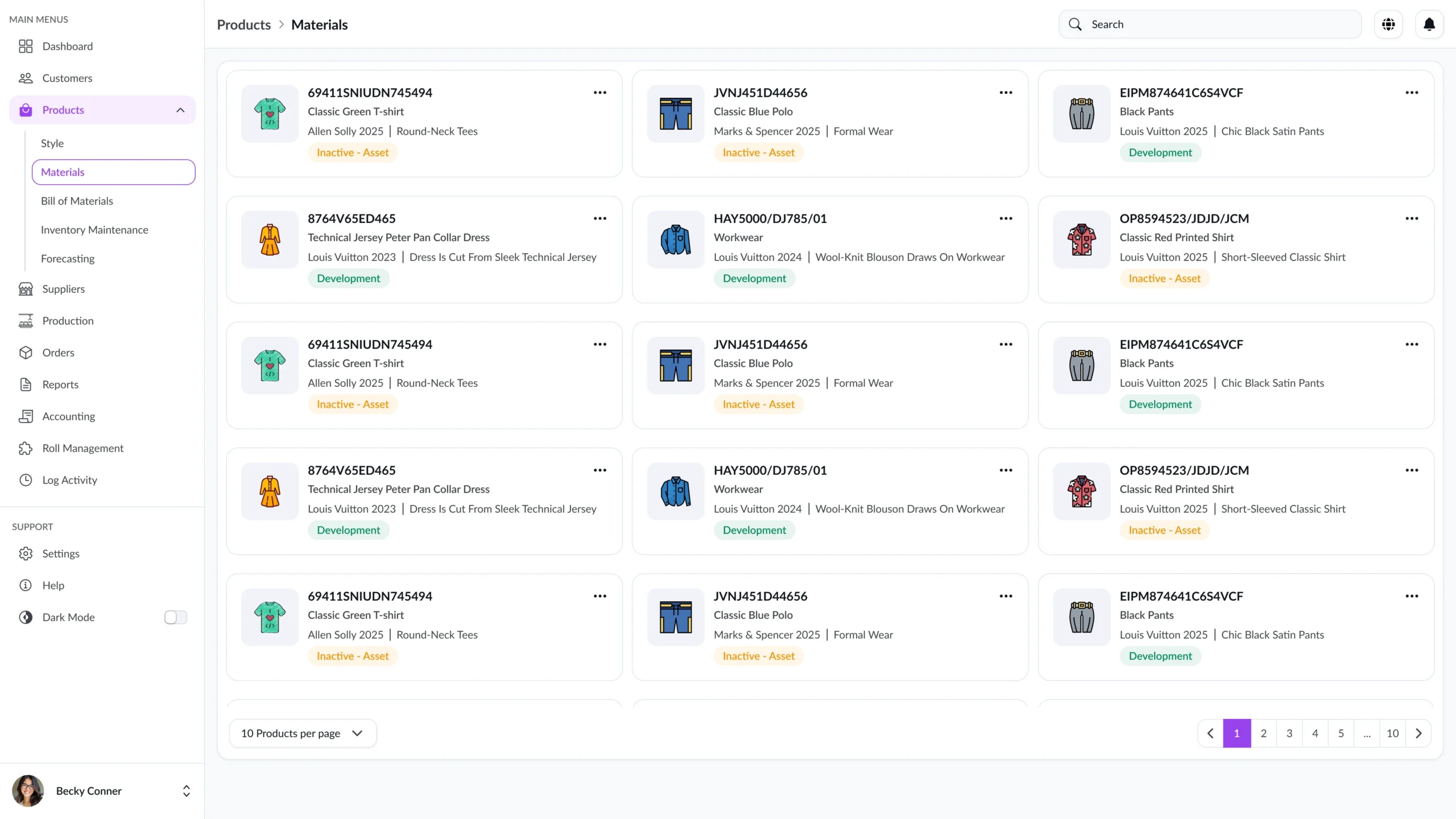

BOM creation

The tool generates the Bill of Materials (BOM), which lists every fabric type and component along with specifications such as supplier, cost, and quantity. Users can view product listings in a centralized space, complete with all details, rather than managing multiple spreadsheets. It reduces errors and gives sourcing teams the clarity they need from the start.

Product testing

Materials undergo quality tests, and their assessment reports and certifications can be directly uploaded into the PLM. This allows every stakeholder to get visibility and ensures potential issues are caught early, avoiding costly mistakes or brand damage later.

Purchase order

Users can generate purchase orders directly from PLM. This syncs with suppliers, linking product specifications and BOMs to actual procurement needs. The process removes the risk of errors caused by disconnected systems and speeds up order placement.

Specifications & tech packs

Users can add product specifications such as points of measure, size graduations, and finishing details. They can generate centralized tech packs that suppliers can access directly from PLM

Sample management

Brands can request samples from factories and track them. They can upload feedback, approve, or reject prototypes within the system. Each sample iteration is logged, creating a clear audit trail for decision-making.

Product costing

We built a cost module that calculates the cost of the garment by combining raw material costs, labor, and overhead. Brands can then add desired profit margins to set the final selling price or set the selling price and costing to get a desired profit margin.

Compliance

The PLM is compliant with the Digital Product Passport requirements, which show material origin, production process, and eco-footprint. This is increasingly demanded by regulators and is mandated by EU laws. Users can also include certifications (organic cotton, fair trade), supplier audits, or sustainability reports.

Feature Highlight: What’s different?

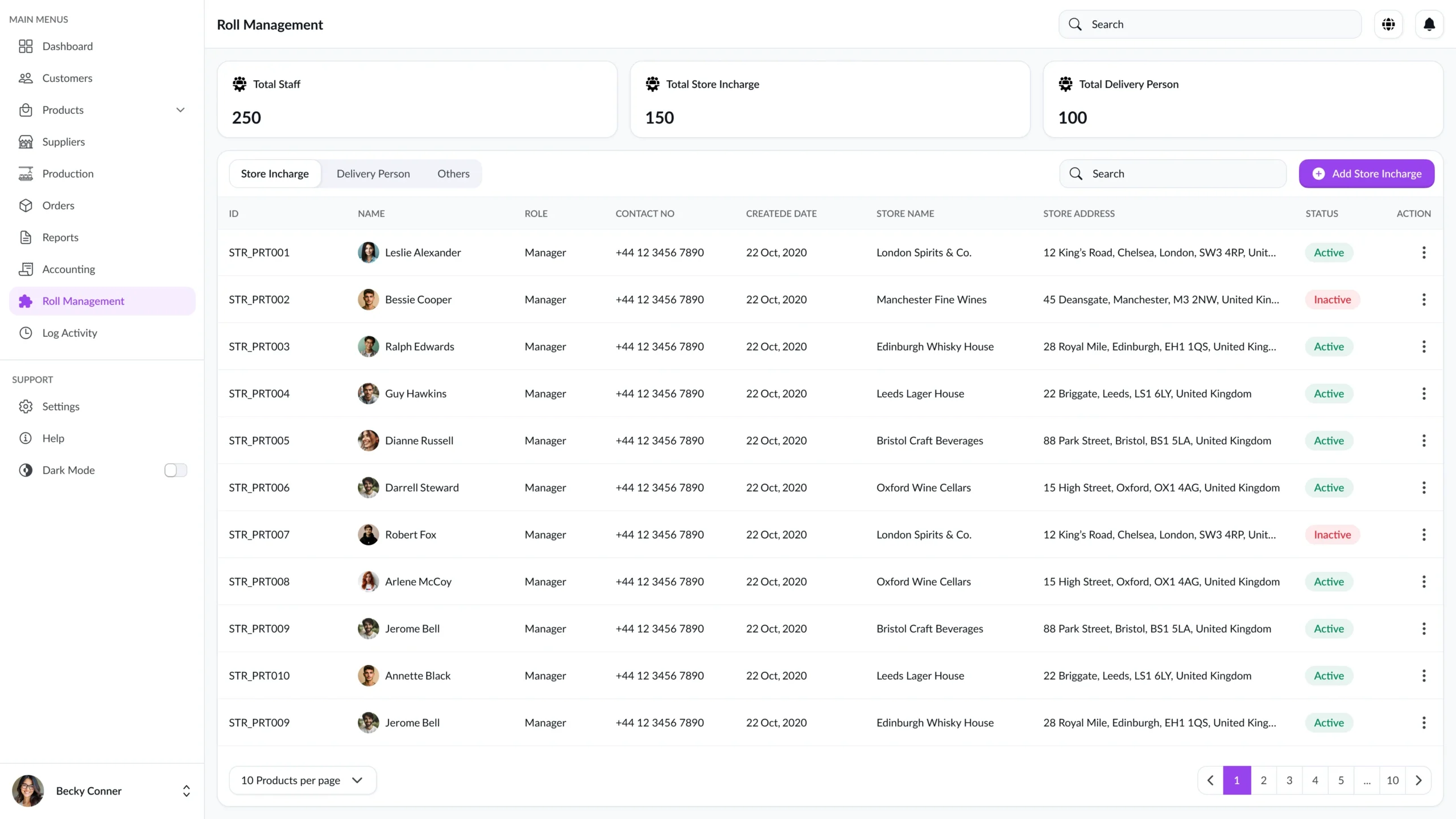

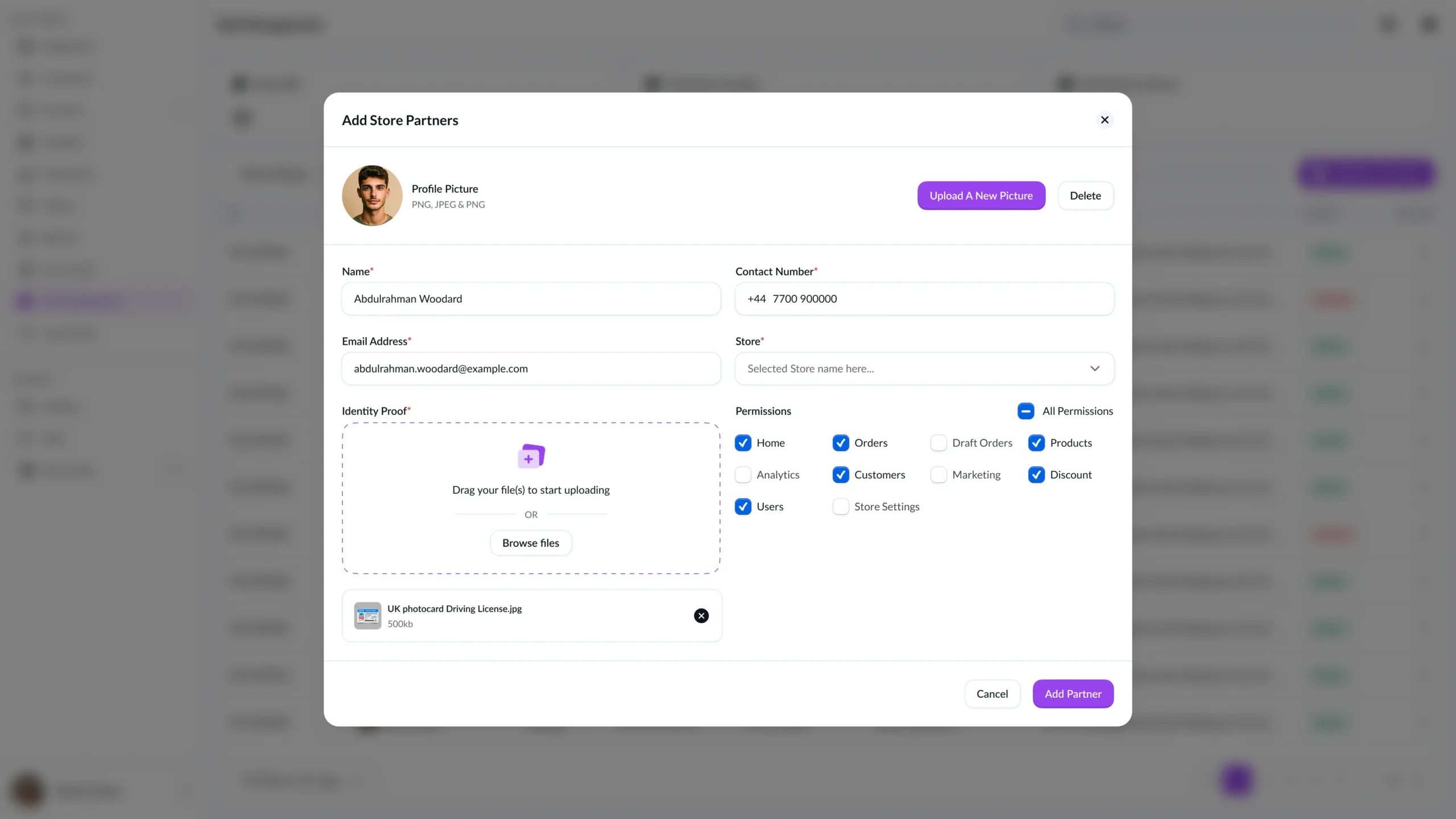

Beyond streamlining day-to-day operations, the PLM comes with advanced features that set it apart. TOPS designed modules that further streamlined workflows and made the platform a one-stop solution for product lifecycle management.

Custom form builders

Giving the complete flexibility for form building was a game-changer for users. For every type of communication, like supplier onboarding, quality inspection checklists, and sample approval requests, a one-size-fits-all approach was inconvenient.

With custom form builders, users can simply drag and drop fields to design their own forms, add custom fields, and brand them to fit their needs. Once created, users can reuse the templates for recurring processes to save time. Not to forget, the built-in feature makes it easy to pull data directly, avoiding manual entry.

Critical path

The critical path feature provides complete transparency into the product journey. Users can view the full history of products and ranges anytime with automatic notifications for key milestones and deadlines. It shows what’s on track, highlights what needs urgent attention, and even auto-adjusts details if dates shift.

Digital Asset Management

No more wasted hours searching for the latest design file or fabrics. We built the Digital Asset Management feature with advanced search and metadata tagging to facilitate users in finding assets instantly using keywords, categories, or custom fillers.

With one central library, your team has immediate access to the right files at the right time. Plus, DAM connects seamlessly with PLM, PIM, and Digital Product Passport for a unified experience.

Digital Product Passport

An increasing number of markets are introducing the concept of Digital Product Passports: A tool for collecting and sharing product data throughout its entire lifecycle. It collects details such as the product’s sustainability, environmental, and recyclability attributes. Our system streamlines this complex process by automatically generating product passports that stay up-to-date with global requirements.

Anyone can see where the product was manufactured, where the raw materials were sourced from, where it is sold, and other details. Beyond compliance, it also aggregates environmental data like CO2 emissions and water usage to support sustainability goals.

Product Information Management (PIM)

It was essential for clients to ensure consistency in product data across channels. Our PIM supports rich media like images and videos, and maintains a single source of truth for all products. This allows brands to quickly onboard to new marketplaces, accelerate product launches, and deliver a seamless experience for customers wherever they shop.

Planning sheet

We added a planning sheet module that allows users to stay ahead of deadlines with dynamic planning. Users can add timelines for every phase of the product lifecycle, and if one date shifts, the rest auto-adjusts. The tool also leverages predictive analysis to suggest realistic completion dates for current productions. It helps brands proactively manage delays before they escalate.

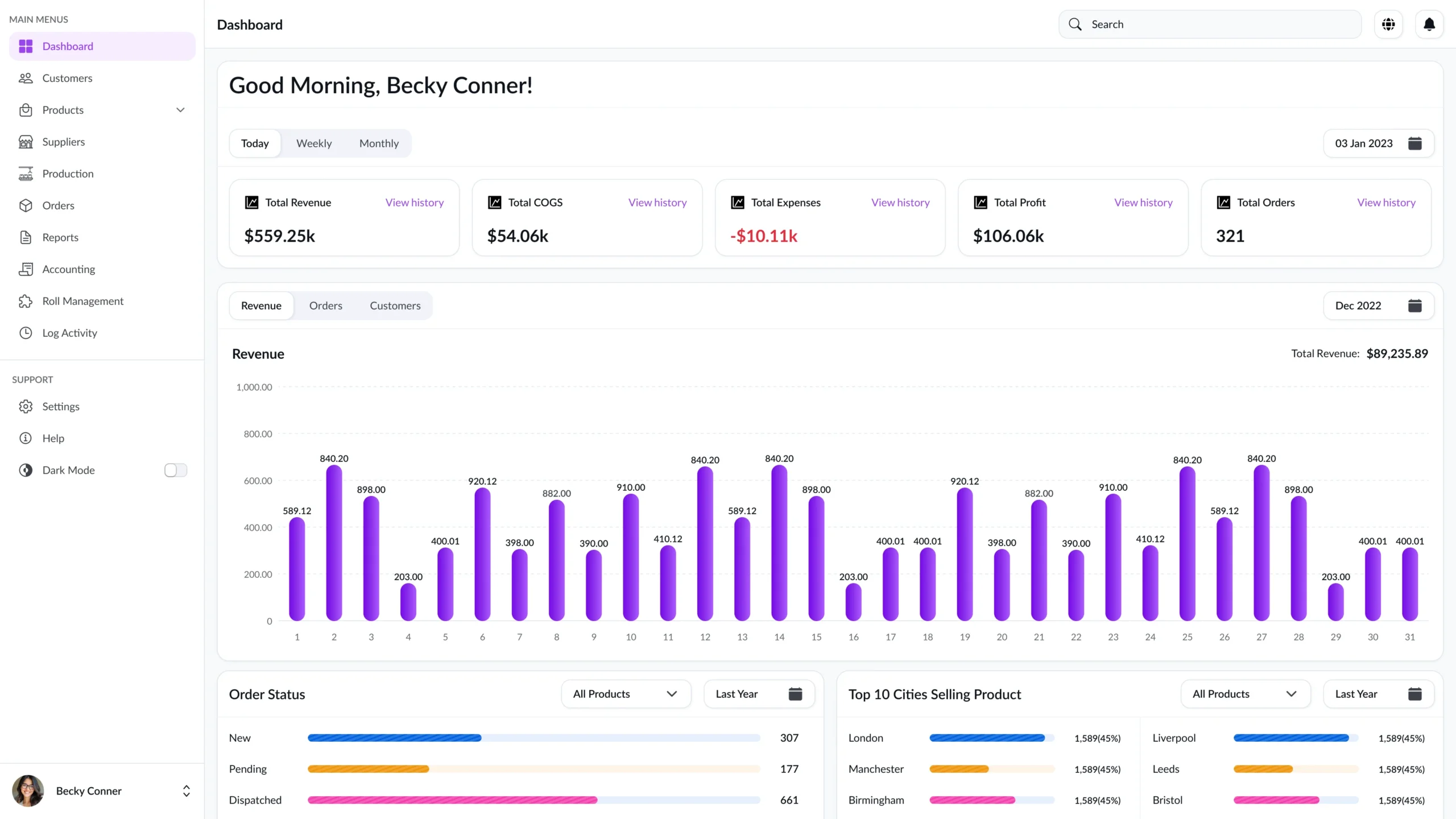

Results: Smarter product management for fashion manufacturers

The impact was immediate, with clients rolling in within one month of deployment. By consolidating processes under one platform, fashion brands experienced measurable improvements.

Brands were able to transform the way products moved from design to market.

For example, for brands with more than 15000-20000 products, manual listing would ideally take weeks if not months. With our solution, they could do it in a matter of minutes.

As a result of cloud-based product management, brands saw the following results:

- Accelerated time-to-market by 25%,

- Reduced product development costs by 25%

- Data errors reduced by 90%

What’s next?

While the PLM solution has already transformed product management for fashion brands, the journey doesn’t stop here. We’re working on new enhancements to make the platform even more seamless and scalable:

Built-in communication

Instead of relying on external tools like Google Chat, teams will soon be able to communicate directly within the platform. This keeps conversations tied to the right product records and avoids platform-switching.

Advanced integrations

We’re working towards integrating with Microsoft Calendar. Deadlines and milestones can be synced with Microsoft Calendar, making it easier for teams to stay on top of approvals and coordination.

Ready to Transform Your Product Journey?

Centralize your data, streamline collaboration, and accelerate time-to-market with a PLM solution built for your industry.